CST evaluates ideas for creating modular robotic systems suitable for the move to creating smart robots that will eventually replace most jobs.

There is of course already some standardisation in the robotics field, the IFR & VDMA et al have various standards. However, these are currently limited and follow the relatively slow pace of current introduction of robotics in mainly the manufacturing industries.

CST considers that we shall see a step-change in the availability and use of robotic devices at some point in the future. This will happen when the costs and performance meet the critical tipping point where many tasks can be automated for significantly less than a human employee.

To get to this point, we set out some ideas below that bring together current trends and potential standardisation to provide a significant and ongoing improvement in capability. Crucially, these ideas, working together, will provide significant potential for cost reduction while at the same time massively broadening the potential automation applications.

There seems to be an obvious path to efficient mass robotic production system that enables a large range of designer robotic devices much more efficiently;

Unlike natural animals, it will be a long time before robots can change their task orientated functionality to meet a specific need. The use of interchangeable core parts, along with additional precisely specific parts will allow quick and efficient production and malleability to achieve similar functionality to that of a more intelligent natural system.

This can be considered as an equivalent to object orientated programming, where re-usable sets of code that have pre-defined and known inputs and output types can be assembled to create a larger program.

The core design needs to enable cross functionality, where any combination can be utilised. This means an industry-wide set of updatable standards.

Examples of such modules are:

An industry-wide cooperative set of standards could allow the creation of specific functionality by industrial sector. The beauty of this approach is that if you need very specific functionality, you only need to create an add-on module that utilise's the other core modules to create your final robot that does a very specific job.

Furthermore, with a store of basic modules, different tasks can be precisely achieved by swapping out modules when required. This means that many different tasks can be cost effectively achieved by having several add-on modules. This leads to a much lower cost of entry (for a company) that has several specific tasks to automate.

Sub Modular

Using the same premise, modules can be built-up from sub-modules. For instance, a movement module may comprise of several joint, leg and feet modules. All modules and sub modules utilise the same standards to create interoperability.

AI systems are now showing they can interpret complex situations and high level language communications.

There is still a massive question of whether current AI systems (such as Chatbots) can output useful robotic commands (see the new Turing test).

These AI systems are expensive pieces of infrastructure and their use must be orchestrated. This can be achieved by a central AI system that pulls in necessary resources as required for the issue at hand. This provides efficient use of these distributed resources. Specific distributed AI resources can be aligned to functions to leverage the effectiveness of a particular module

Some tasks need more processing power than others. As Smartness is expensive, a modular approach means that the final robot only uses the AI / processing power required for each job at hand.

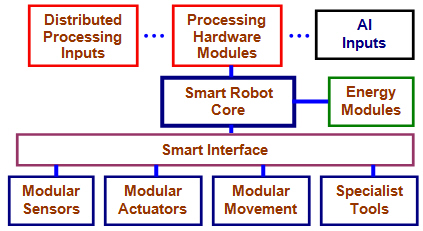

This can be achieved in two ways, Firstly required is a basic range of processing modules that add core (local hardware) processing power:

Secondly, there must be ‘online’ distributed processing at various levels of complexity, speed and data functionality. Some of this will be highend AI systems that can help decision making and understanding of human input. This source of processing and data must also be ‘modular’ in the sense that the final smart robot configuration will only call upon the necessary level of smart help that is required to achieve the task in hand.

Thirdly, there needs to be a local core controller that co-ordinates the use and application of each additional processing system. This should also be capable of, (when needed), linking directly to a core AI system that can help with central control tasks.

This means that two robotic devices using the same or similar modules, will be able to achieve different jobs due to the distributed resource they tap into. For instance, a single robot system may be used to move around stock parts using little or no distributed processing. The same basic robot may be used for a more complex task; say analysing and controlling a simple production line.

This could be achieved by accessing high level distributed and potentially AI processing and online data to make sense of the production line data, seek solutions and then co-ordinating the start process. For this more complex task the smart robot may well contact several AI systems that can help at each step of the process, especially for error and safety checks. The core level AI would handle the interface between the many AI systems and error check.

A major part of the necessary interoperability across all modules are the precise standards that allow this to occur. These should allow for change as standards often become a significant barrier to ongoing development. Perhaps a way of achieving this would be to create a ‘go between’ interface module that sits between each and every module and adapts the signals and data to adjust for changing functionality and changing standards.

Such a ‘go between module’ might interrogate and check each adjoining module or sensor and adjust the inputs and outputs to make the most of the full abilities of each. For instance an older less capable module cannot utilise the latest set of functional calls, or process data steams at the current rate. The go between module would adapt the speed and addressable functionality to create the required input and output for the attached newer module. If an older module is incapable of the necessary functionality, the go between would not allow its use and advise the core processing module.

This calls into question the functionality of the communication system within the robot modules and across the final configure robot. To enable such functionality, there needs to be a central ‘nervous’ system that links each ‘go between module’ to the main processor and thus the distributed online processing system. With such a linked communication system it can be seen that each module can be precisely controlled irrespective of its functionality, and in real time. Such a system would allow, internal reconfiguration for continued use, for instance if a leg module fails, the robot could automatically reprogram itself as a three legged device.

This creates a very flexible overall system and enable each modular robot to maximise it's capabilities throughout it's lifespan. This also builds a powerful mechanism for error checking and prevention of harm in the event of a module failure.

One of the most important issues along our proposed path of ‘Smart Robotics’ is to drive down manufacturing costs. We know that this happens when volume meets demand. To gain more quickly such an advantage, the modular approach provides a playing field for manufacturers across the world to compete.

Many smaller businesses would be empowered to create niche modules that do a very specific task. There are many such sector driven businesses already and they add value to the sector. For instance, medical devices require such an approach, smaller businesses are ideal to provide ongoing innovation as they understand exactly what is required.

Larger businesses can use their size and volume manufacturing to provide core modules. With interchangeability built into the flexible specification path, good competition will create a mass market for such core modules.

Provided the standards are high and flexible, this modula approach provides for a much quicker transition to volume manufacturing of smart robots and their applications in many industry and consumer sectors.

Let’s suppose that we now have a well engineered and effective smart robot. This consists of many parts to create many sub-assemblies. With our AI coupled smart robot there is no reason why it cannot be trained to assemble a new smart robot from the parts list.

All these parts would be made in volume manufacturing plants. They would also be designed, of course, for quick assembly by a smart robot. This means that (like car manufacturing) the parts are designed to fit together without modification and without excessive tooling.

Once we have a trained smart robot making another smart robot successfully, the simple arithmetic of robots making more robots becomes interesting.

Presume that each robot takes two hours to assemble. The initial robot makes 12 in one complete day (it doesn’t need to sleep or rest and has swap out batteries). In one month that provides 360 new robots. The next month our 360 new robots assemble 12,960 robots, in the third month we can make 46 million robots (provided we had the space and the parts). So even if it takes a whole day to assemble a robot, in the forth month we still make 12 million robots.

We can see that this is interesting, the robot assembly is clearly exponential. If we can then utilise some of these smart robots to help within the manufacture and storage and movement of all the volume parts, we can see that in a short timescale we have an extremely powerful low cost production system for smart robotics. This whole process, linked to AI support systems creates a virtuous manufacturing cycle. Within a few years, the world could have tens of millions of smart robots able to do many different complex tasks for individuals, factories, shops, offices and within healthcare, elderly care and the home.

CST cannot understand why this simple thought experiment has not reached out to manufacturers of robotics. They have not even started the process of developing a modular smart robot. (including Musk with his Optimus robot). Yet, if the world wants to innovate, CST cannot think of a better way forward. The world needs to collaborate on this and design and create the first smart robot – then everything can change exponentially.

Unfortunately, humans (men) being the xxxx's they are, the first driver of this technology will be weaponisation. An army of pre-trained killer robots to swarm wherever you want. The ultimate invading, unstoppable throw-away army. An army controlled by satelite based AI comms and commanded from a safe place many thousands of miles away. Oh, who could resist such an 'exciting' prospect. Just watch.

CST

Nov 2020

Here we evaluate ideas for creating 'smart modular robotic' systems that leverage current technology.

The speed of advancement for smart robotic technology dictates many of the outcomes for the unfolding issues within our societies - from economic theories to cheap clean energy and transportation.